What is Formwork

Fresh concrete needs to be kept in its intended shape till its hardens and formwork achieved this purpose.

Formwork (shuttering) in concrete construction is used as a mould for a structure in which fresh concrete is poured only to be harden subsequently.

Good formwork should be rigid with sufficient number of support to withstand the entire load till the concrete harden.

Even though there is a large variety of formwork, the generally use formwork in house building segment and any other type of building is made of steel and wood. At Mauri-placque Ltd, we deal mainly with steel formwork.

The stand supporting the formwork is kept truly vertical and is rest on firm base.

The centering is to properly align to the required level and dimension.

The gaps between the shuttering are sealed to prevent leakage of slurry and a thin film of oil or grease is apply on the surface of the formwork to ensure easy de-shuttering. Before applying the concrete, all dust, stone, chippings etc if any are to be removed from the formwork.

Formwork should be removed only after concrete has attains sufficient strength

Proper formwork is essential for concrete to harden in the desire shape and for it to become strong and durable. At Mauri-Placque Ltd we make sure that the formwork is robust, leak proof and is supported properly

A good formwork should satisfy the following requirements:

1. It should be strong enough to withstand all types of dead and live loads.

2. It should be rigidly constructed and efficiently propped and braced both horizontally and vertically, so as to retain its shape.

3. The joints in the formwork should be tight against leakage of cement grout.

4. Construction of formwork should permit removal of various parts in desired sequences without damage to the concrete.

5. The formwork should be set accurately to the desired line and levels should have plane surface.

6. The material of the formwork should not warp or get distorted when exposed other to the elements.

7. It should rest on firm base.

Steel forms compared with timber formwork:

1. Steel forms are stronger, durable and have longer life than timber.

2. Steel forms can be installed and dismantled with greater ease and speed.

3. The quality of exposed concrete surface by using steel forms is good and such surfaces need no further treatment.

4. Steel formwork does not absorb moisture from concrete.

5. Steel formwork does not shrink or warp.

Period of Removal of Formwork

The removal of concrete formwork should be carried out only after the time when concrete has gained sufficient strength, at least twice the stress to which the concrete may be subjected to when the formworks are removed

The rate of hardening of concrete or the concrete strength depends on temperature and affects the formwork removal time. For example, time required for removal of concrete in winter will be more than time required during summer.

Special attention is required for formwork removal of flexural members such as beams and slabs.

Generally a concrete of 150mm may take approximately 12 days to harden. Bigger concrete size may take a maximum of 21 days to harden. The building engineers will provide the exact number days which is required for the concrete to harden and strength properly.

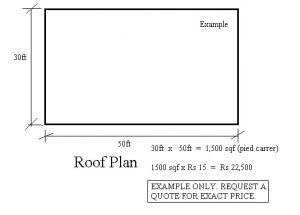

Payment Calculation

Measurements of formwork (shuttering) is required for payment to Mauri-Plaque Ltd.

The payment will depend on whether the project includes Roof edges, above ground floor level, easy truck access to construction site,

cornice and whether extra labours are required (Generally bigger size buildings).

All items are taken in consideration before submission of a quote.

The formwork is measured in terms of area that is in contact with the concrete surface.

For example, the formwork for shuttering of roof will be calculated as the surface area of four sides.

This is an example only. For a proper quote please click on “Request a Quote” fill up the quote request or call us.